Keneco Carton Flow Rack

Keneco carton flow rack solutions are gravity flow, live storage systems typically used for carton handling and order picking operations in warehouses, distribution centers

Designed to increase operational efficiencies that result in significant cost and labor savings, the Keneco systems use inclined shelves equipped with

With just one carton of each line item located on the pick face, the picker is presented with a large number of SKUs over a smaller area. By significantly reducing

Built for performance and reliability, compared with other systems, the rugged, trouble-free construction of

- Better carton flow

- Ergonomic design

- Reduced picker fatigue

- Less walking

- Increased productivity

.

- Reduced time-to-market

- Improved inventory control

- Enhanced efficiencies

- Significant savings in labor and costs

Your Premiere Source for All Carton Flow Rack Types

Keneco is unique in the industry for offering all carton flow rack types. Whether you’re looking for custom or standard carton flow, or to convert your pallet racks to carton flow, you will find it here.

Call 1-800-932-0121 to speak with a knowledgeable Keneco carton flow specialist.

With a singular product focus and more than thirty years providing individualized customer solutions and care, let Keneco be your premiere choice for standard and custom carton flow solutions.

Keneco Carton Flow Rack Brochure

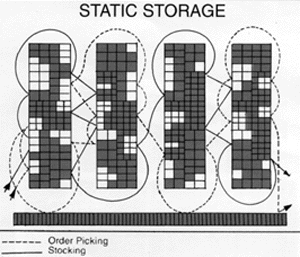

Static Storage

Traditional pallet racks and shelving represent static storage solutions. Static storage occupies double the amount of floor space compared with gravity flow systems. Typically requiring 2 to 4 times more pickers and more walking, static storage is both inefficient and labor intensive.

Such inefficiencies add to time and cost, causing inventory control, stock rotation and picking accuracy problems that slow productivity and time-to-market.

Gravity Flow Rack

A Keneco gravity flow rack is a live storage system that moves product from the stocking to the picking side by gravity, along inclined shelves equipped with roller tracks. The Keneco gravity flow rack system saves time, labor and floor space. Floor space is saved because fewer aisles are needed to reach the same amount of products. A first in, first out stock rotation is always achieved. The fact that just one carton of each line item is located on the pick face means that a large number of SKU’s are presented to the picker over a small area. Less time spent walking and searching for items means fewer pickers with less supervision, which increases efficiency and gives you significant labor savings.